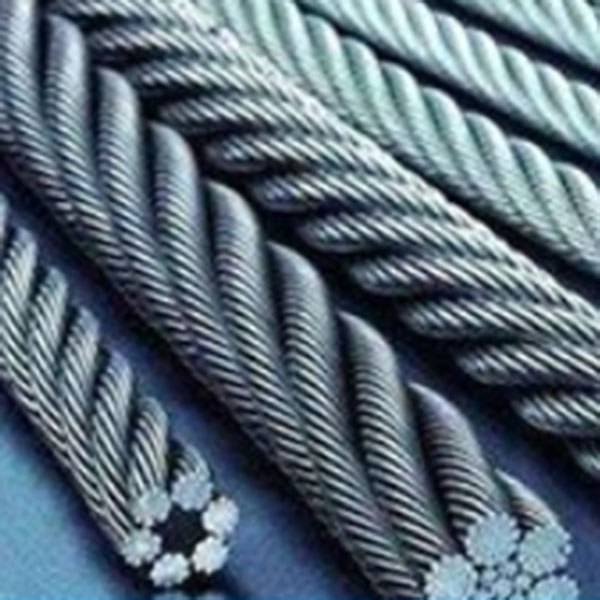

اعليٰ معيار جي لفٽ اسٽيل وائر رسي

1. هي وضاحت رفتار محدود ڪندڙ تار رسي، گهٽ رفتار، گهٽ لوڊ لفٽ لاءِ موزون آهي.

2. اسان توهان جي گهرجن مطابق ترتيب ڏئي سگهون ٿا.

| نالي ماتر رسي جو قطر | 6*19 ايس+پي پي | گھٽ ۾ گھٽ بريڪنگ لوڊ | |||

| اندازاً وزن | ٻٽي ٽينسل، ايم پي اي | سنگل ٽينسل، ايم پي اي | |||

| 1370/1770 | 1570/1770 | 1570 | 1770 | ||

| mm | ڪلوگرام/100 ميٽر | kN | kN | kN | kN |

| 6 | 12.9 | 17.8 | 19.5 | 18.7 | 21 |

| 8 | 23 | 31.7 | 34.6 | 33.2 | 37.4 |

1. قدرتي فائبر ڪور (اين ايف سي): ٽريڪشن مشين جي تار رسي لاءِ مناسب آهي جنهن جي رفتار ≤ 2.0 ميٽر/سيڪنڊ آهي.

2. عمارت جي اوچائي≤80M

| نالي ماتر رسي جو قطر | 8*19 ايس+اين ايف سي | گھٽ ۾ گھٽ بريڪنگ لوڊ | |||

| اندازاً وزن | ٻٽي ٽينسل، ايم پي اي | سنگل ٽينسل، ايم پي اي | |||

| 1370/1770 | 1570/1770 | 1570 | 1770 | ||

| mm | ڪلوگرام/100 ميٽر | kN | kN | kN | kN |

| 8 | 21.8 | 28.1 | 30.8 | 29.4 | 33.2 |

| 9 | 27.5 | 35.6 | 38.9 | 37.3 | 42 |

| 10 | 34 | 44 | 48.1 | 46 | 51.9 |

| 11 | 41.1 | 53.2 | 58.1 | 55.7 | 62.8 |

| 12 | 49 | 63.3 | 69.2 | 66.2 | 74.7 |

| 13 | 57.5 | 74.3 | 81.2 | 77.7 | 87.6 |

| 14 | 66.6 | 86.1 | 94.2 | 90.2 | 102 |

| 15 | 76.5 | 98.9 | 108 | 104 | 117 |

| 16 | 87 | 113 | 123 | 118 | 133 |

| 18 | 110 | 142 | 156 | 149 | 168 |

| 19 | 123 | 159 | 173 | 166 | 187 |

| 20 | 136 | 176 | 192 | 184 | 207 |

| 22 | 165 | 213 | 233 | 223 | 251 |

1. IWRC لاءِ، رفتار> 4.0 ميٽر/سيڪنڊ، عمارت جي اوچائي> 100 ميٽر

2. IWRF لاءِ، 2.0< رفتار≤4.0m/s، عمارت جي اوچائي≤100m

| نالي ماتر رسي جو قطر | 8*19 ايس | گھٽ ۾ گھٽ بريڪنگ لوڊ | |||||||

| اندازاً وزن | سنگل ٽينسل، ايم پي اي | ||||||||

| 1570 | 1620 | 1770 | |||||||

| آئي ڊبليو آر سي | آئي ڊبليو آر ايف | آئي ڊبليو آر سي | آئي ڊبليو آر ايف | آئي ڊبليو آر سي | آئي ڊبليو آر ايف | آئي ڊبليو آر سي | آئي ڊبليو آر ايف | ||

| mm | ڪلوگرام/100 ميٽر | kN | kN | / | kN | ||||

| 8 | 26 | 25.9 | 35.8 | 35.2 | 36.9 | 35.2 | 40.3 | 39.6 | |

| 9 | 33 | 32.8 | 45.3 | 44.5 | 46.7 | 45.9 | 51 | 50.2 | |

| 10 | 40.7 | 40.5 | 55.9 | 55 | 57.7 | 56.7 | 63 | 62 | |

| 11 | 49.2 | 49 | 67.6 | 66.5 | 69.8 | 68.6 | 76.2 | 75 | |

| 12 | 58.6 | 58.3 | 80.5 | 79.1 | 83 | 81.6 | 90.7 | 89.2 | |

| 13 | 68.8 | 68.4 | 94.5 | 92.9 | 97.5 | 98.5 | 106 | 105 | |

| 14 | 79.8 | 79.4 | 110 | 108 | 113 | 111 | 124 | 121 | |

| 15 | 91.6 | 91.1 | 126 | 124 | 130 | 128 | 142 | 139 | |

| 16 | 104 | 104 | 143 | 141 | 148 | 145 | 161 | 159 | |

| 18 | 132 | 131 | 181 | 178 | 187 | 184 | 204 | 201 | |

| 19 | 147 | 146 | 202 | 198 | 208 | 205 | 227 | 224 | |

| 20 | 163 | 162 | 224 | 220 | 231 | 227 | 252 | 248 | |

| 22 | 197 | 196 | 271 | 266 | 279 | 274 | 305 | 300 | |

لفٽ جي تار جي رسي لاءِ استعمال ٿيندڙ سڀ کان ننڍي پيماني تي مسافر لفٽ. ڪمرشل رهائشي ضلعن ۾، لفٽ جي تار جي رسي جون وضاحتون عام طور تي 8*19S+FC-8mm، 8*19S+FC-10mm هونديون آهن. شاپنگ مالز 12mm، 13mm، ۽ لوڊ لفٽ اسٽيل رسي جون وضاحتون 12mm، 13mm، ۽ 16mm قطر جون ٿوريون وڏيون لفٽ رسي جون وضاحتون استعمال ڪندا آهن.

اسٽيل وائر رسي آرڊر ڪرڻ وقت، توهان کي گذارش آهي ته اسان کي هيٺ ڏنل مڪمل معلومات ڏيو:

1. مقصد: ڪهڙي رسي لاءِ استعمال ڪيو ويندو؛

2. سائيز: رسي جو قطر ملي ميٽر يا انچ ۾؛

3. تعمير: تارن جو تعداد، هر اسٽرينڊ ۾ تارن جو تعداد ۽ اسٽينڊ جي تعمير جو قسم؛

4. ڪور جو قسم: فائبر ڪور (ايف سي)، آزاد تار رسي ڪور (IWRC) يا آزاد تار اسٽرينڊ ڪور (IWSC)؛

5. ليٽ: ساڄي باقاعدي ليٽ، کاٻي باقاعدي ليٽ، ساڄي لنگ ليٽ، کاٻي لنگ ليٽ،

6. مواد: روشن (غير لوهي)، لوهي يا اسٽينلیس اسٽيل؛

7. تار جو گريڊ: تارن جي تناسلي طاقت؛

8. لوبريڪيشن: لوبريڪيشن گهربل آهي يا نه ۽ گهربل لوبريڪنٽ؛

9. ڊيگهه: تار جي رسي جي ڊيگهه؛

10. پيڪنگ: آئل پيپر ۽ هيسين ڪپڙي سان ويڙهيل ڪوئلن ۾ يا ڪاٺ جي ريل تي؛

11. مقدار: ڊيگهه يا وزن جي لحاظ کان ڪوئلن يا ريل جي تعداد جي لحاظ کان؛

12. تبصرا: شپنگ جا نشان ۽ ٻيون خاص گهرجون.

ڊگھي عرصي جي آپريشن دوران، تار جي رسي تي چکڻ وارو تيل بتدريج گهٽجي ويندو. تنهن ڪري، تار جي رسي کي باقاعدي طور تي چکڻ وارو هجڻ ضروري آهي، جيڪو تار جي رسي جي سروس لائف کي وڌائي سگهي ٿو، ۽ لباس کي گهٽائي سگهي ٿو ۽ ريليبريڪٽنگ ذريعي زنگ کي روڪي سگهي ٿو. مڪمل طور تي چکڻ واري تار جي رسي جي مقابلي ۾، خشڪ تار جي رسي جي سروس لائف کي 80٪ تائين گهٽائي سگهجي ٿو! تار جي رسي جي ريليبريڪيشن هڪ تمام اهم ڪردار ادا ڪري ٿي. اسان عام طور تي T86 چکڻ وارو تيل چونڊيندا آهيون، جيڪو هڪ تمام پتلي مائع آهي جيڪو آساني سان تار جي رسي جي اندر داخل ٿي سگهي ٿو. ان کي اسپري ڪرڻ لاءِ صرف برش يا پورٽيبل 1 ليٽر بيرل جي ضرورت آهي. استعمال جي جڳهه اها هجڻ گهرجي جتي تار جي رسي ٽريڪشن شيو يا گائيڊ ويل کي ڇهي، ته جيئن تار جي رسي جو لوبريڪنٽ تار جي رسي ۾ وڌيڪ آساني سان وهي سگهي.